Bespoke Jeans and The World of Raw Denim

The following article is adapted from Season 1, Episode 8 of my podcast, Tailoring Talk with Roberto Revilla. You can download & listen directly here or by searching for Tailoring Talk on your favourite podcast platform.

Now, as you would expect, my favourite clothes are my fabulous suits - but my second favourite? They have to be my jeans! So many of us are obsessed with denim, and so many of us are on the same quest: the search for the holiest of Holy Grails… perfect fitting jeans.

Join me as I take you on a 4,500 mile trip to Tupelo, Mississippi to meet Blake Cocanaugher of the BlueDelta Jeans Company. Together we’re going to find out a little bit about the history of denim & how the modern jean came to be, discover the lucrative past time of jean prospecting & dive behind the scenes to find out how this little company creates a perfect fitting jean every single time. Enjoy!

Roberto Revilla: At any point of any given day, 50% of the world’s population is wearing denim. There are few better that could join me today to deep-dive into our obsession with jeans. I’m joined all the way from Tupelo, Mississippi by Blake Cocanaugher of BlueDelta Jeans. Blake, welcome to the show, how are you?

Blake Cocanaugher: I’m doing very well Bobby, thank you for having me on.

RR: How have things been the last few months with Covid and the whole pandemic situation over there?

BC: You know it’s been an interesting year like it has been for everybody. We were fortunate through the first 6-8 months or so, we did a lot of PPE production, made masks and gowns for government entities here in the State of Mississippi, we were really proud to be able to do that and fortunate because we were able to keep all of our staff on board. But we’re back, we’re making jeans at a clip, even faster than we were a year ago, so we count ourselves very fortunate. During Covid everyone got very accustomed to wearing sweat pants at home so now our moniker is “Let’s trade in those sweat pants but keep you in something comfortable” and so that’s where custom jeans come into play.

RR: I’m really shocked actually. In Britain we expect it, I don’t know where we get this reputation from of being well-dressed. I don’t know if it’s what you guys see of us from movies and on television shows and that sort of thing, but trust me, if you get out here it’s not quite the case. There are some well-dressed people but on the whole, there’s a lot of work to be done! And I probably shouldn’t complain about that because it means there’s a whole market opportunity there for me.

We definitely saw a lot of people and heard a lot of people telling us proudly how they’d ditched suits and ditched jeans and were wearing shorts… yeah we had actually gone a step below jogging bottoms over here. Shorts and t-shirts even up to now. Crazy. I’m really surprised because I would have assumed - and maybe this is me just stereotyping in my own mind from what I see of America on TV - that jeans would be the lowest common denominator out there during the pandemic and working from home.

BC: I hate to say you’re wrong on that one! In American media and American culture we definitely view Britons as wearing three-piece suits everywhere you go, probably a consequence of James Bond movies and what we see on Netflix. In the United States, denim increasingly, like everywhere else in the world is becoming more and more comfort wear as stretch materials get added into denim. But still a big joke over here is sweat pants and like you said, work out shorts at home during the day. It’s kinda like the stuff you see sometimes on ESPN over here, they’ve got these old commercials of the ESPN anchors wearing a suit jacket and tie, then they step out from behind the desk and they’ve got swim trunks on or something. That’s kind of become the reality unfortunately.

RR: There was that video that went viral last year during the pandemic where I think it was a sports anchor, some guy on CBS or one of those channels in the States. He was being interviewed, but he was in his underwear, I think it was literally in his boxers. It’s shocking… but we are unlocking gradually over here in the UK and we seem to be on track so far. So with that we’re hoping that we’ll also see a general return to some level of decorum. Let’s see how that goes.

2020 becomes almost this lost year as far as that quote goes or that fact I gave a the top there: at any one point in time, on any given day, 50% of this planet’s population are wearing denim. That’s just crazy right? But then are we surprised?

BC: It’s a crazy statistic and I do hear that one a lot. It always catches me off guard but you think about the history of denim - it’s really not that old of a fabric, you’re talking about a couple hundred years and blue jeans in their modern sense came to fruition in really the 1850s. But denim became popular because it is a workmen’s fabric. It’s a sturdy material, it lasts you a good long while. You don’t have to wash and clean it all the time because of the nature of the material. So you think about the overall population of the world, most people on a day to day basis are doing some form of labour and denim is the material that fits the bill for what they may need to wear.

So definitely an odd statistic but when you get into it a little bit it makes sense.

RR: We’ll come back to the washing of denim in a little while because its a touchy subject especially over here, because I get asked by customers “How do I look after these, do I wash them?” and I say, “Well, you should never ever wash jeans. They put dry clean only on them but you shouldn’t even do that.” They’ll look at me and they’ll be like “Really?” with a look of disdain, “What happens when they get dirty and smelly?” and I actually have to confess I don’t know. But I don’t wash mine and the reason is because I’ve got 7 or 8 pairs of them. And they all do different things, my jeans all have their own individual personalities now as time has gone on which is also very cool.

So going back to the start, because you said quite rightly that they came about as a form of workwear, the story started with Jacob Davis in the USA. Because jeans actually, the fabric itself originates from Europe.

BC: Yes, so denim is one word in the English language but really it came about as two words. Denim was first invented or created in Nimes, France and so when it started showing up all over the world it was referred to as de Nimes (of France) as in of Nimes, France.

RR: So the fabric eventually makes its way over to the USA and Jacob Davis, who was a tailor, he had this customer who was a huge mountain of a man who came in and had a demand for pants that just wouldn’t bust at the seams and I guess this is where the modern version of the jean came from.

BC: Right so as you said, as the story goes, this client came in in, needed a pant that would be durable and long lasting and would fit him. So Jacob Davis makes this pant and I guess the client got it, and showed everyone how cool it was and then demand started growing. Jacob Davis then starts looking around for a supplier that he wanted to use to make this new type of pant that he had invented and goes to this company that was out in San Francisco at the time, Levi Strauss, that we all now know. They looked at what he was making and what materials he was buying for them and they loved it, so Jacob Davis joins forces with Levi Strauss, they sign a contract and they start mass manufacturing denim out in the Western United States during the Gold Rush.

Back to what I said about it earlier being a workmen’s material, you have guys that are exploring the Wild West, living in desert conditions, panning for gold… they needed something that just lasted. Thin, lightweight materials at the time would tear up and wouldn’t survive the sandstorms and sleeping on the ground at night and so, here all of a sudden, you have this material that is tough, and it lasts forever and not only that but it’s dyed dark blue, which hides stains and blood and this and that that you pick up on a day to day basis. A match made in heaven.

RR: Have you heard of Indiana Jeans? It’s not a jeans company - I might be able to teach you something here. There’s a guy called Britt Eaton and he is also known as Indiana Jeans. Like Indiana Jones. He’s an explorer. He goes travelling around the Old West, places like Lone Pine, abandoned mines in California… what he does is, in the same way the Gold Rush prospectors were panning for gold, he goes panning for jeans.

But jeans that were discarded anywhere from 50 to over 100 years ago. So these old abandoned mines, he goes rooting around the remains of these places, and he’s just trying to find jeans that were discarded by prospectors, workers, miners, you name it. Whoever was out there at that time, cowboys, you know - but that’s what Britt does. He’ll find jeans that have been discarded that are still there after all this time, under all this trash and then he sells them.

So these are jeans that back in that would have cost $1.25, he’ll sell them for anything from $2000 to $3000 to $100,000. Because there are collectors all over the world, particularly in the Far East who love this sort of stuff and are paying huge sums of money for these sorts of things. So my question is, did you guys get your business model wrong when you started? Because this guy’s making a killing out of old stuff that exists already! Isn’t that amazing?

BC: Ha ha! Well I’ve successfully avoided having to go into mines on a day to day basis so I think I might be ok with what we’ve done here. So I’ve heard about this guy - I didn’t have the name and the story put together - but I seem to recall here a couple of years ago a pair of 150-160 year old jeans sold for something like $250,000 at auction, that I believe were an original pair of Levi Strauss jeans…

RR: The one pocket jean. Yep that was him. He talks about the one pocket as being the Holy Grail of Jean Prospecting. If it wasn’t for the pandemic and my inability to fly out to your country I’d have been there a year ago just hunting around for this stuff. But the point of the story is that it’s testament to the fabric and how long these things last that this guy can go to some abandoned mine that’s been disused for 100 years and find this amazing piece of clothing that has just been preserved under rubble and junk and whatever else, clean them up a little bit and then sell them on for huge sums of money. But the point is that the fabric itself has not deteriorated or degraded in any way. Can you help shed some light as to why that is? Because anyone would think that cotton being a natural fibre would just break down and turn to dust!

BC: One of things that is probably of substantial help there is that in the early days of denim, they made what we would now call raw denim. Most jeans you buy at the store is made with rinsed denim, so basically they make a denim material, it comes off the looms, its dyed and then its washed and dried, its chemically treated. There’s definitely some benefits to that, it helps the fabric maintain it’s colour better - the flip side of it is that it helps knock some colour off depending on what you want to do with it, so then it gives you that nice, distressed looking jean that you can buy. One of the other big benefits is that because the fabric, the cotton fibres, are already shrunk, it allows you to wash and dry jeans, which is what most people know as the proper method of taking care of a pair of jeans. For that same reason, because it is pre-shrunk it doesn’t hold its size as well. You put them on first time in the morning when they’re out of the dryer and they fit nice and snug how you want them, and by the end of the day you’re ratcheting your belt to the next hole to get them to stay on. So you have these two different types of denim but that rinsing of the denim is what makes denim such a disposable piece of clothing. You don’t buy a cheap pair of jeans at the store expecting them to last you a lifeline, because the fabric is just not meant to do that. 160-170 years ago, they just had one way of doing it. It came of the loom, then it was dyed, then it was sent off to make the fabric. I’m not saying that’s the only reason, I’m sure there are a lot of people out there a lot smarter than I that could give you a more scientific reason, but you had thick heavy materials that weren’t saturated with a bunch of chemicals… buried under dusts and rocks for over 100 years is probably not how I would want my jeans to be treated but it is one way to preserve them.

RR: That’s thing about denim, it’s one material that adapts itself to its environment. Its really interesting what you were saying there because before I found out about you guys and started working with you I was buying jeans off the peg and used to struggle with it because I have big thighs, and so I could probably fit into a 34 jean but would have to size up to a 36 to get my legs in, and then the waist and seat were always too big so I’d have to get them taken in. But within a day of wearing them they’d just wouldn’t fit again, they’d be loose and floppy so I’d have to stick them in the washing machine to try and shrink them down a little bit. Then you wear them and the first few hours they’re absolutely fantastic and then at the end of the day you tightening the belt because they’ve gone loose again, and then you repeat the cycle. A lot of people go through the same thing until they get a pair of our bespoke jeans. So what is about the ingredients, the fabrics that you guys have selected that reduces the need for customers to go through that very painful process?

BC: There’s a couple different elements. The fabrics we use are a modern performance version of what I was mentioning - a raw denim material. We sell what would be considered a light to mid weight denim material, so people think of raw denim and think really heavy, the pair of jeans you can stand in the corner when you’re not wearing them. Ours are not that. We want our jeans to be comfortable because our typical client is a lady or gentlemen who is wearing their jeans to the office with a sports jacket, they don’t want to have to break in this monster pair of denim. But we do have added stretch to the fabric, using lycra which gives the stretch that spandex might. One of the big benefits to it though is it it has incredible recovery. It’s going to give and stretch as you move but but it will always come back to that same size. So those are two big things that make our jeans just a good lasting comfortable pair, in addition to the tailoring. We take 16 measurements to create every pair of jeans we make, we personally pattern every jean and then its cut and sewn by hand at our shop here in Mississippi. There’s a lot of love and care that goes into making a pair of BlueDelta Jeans, just like there’s a lot of love that goes into make a custom shirt or custom suit over there on Savile Row.

RR: It’s amazing still even today when I have a new bespoke jeans customer who tries a pair on for the first time - the look on their face the second they put them on, I don’t even need them to tell me what’s going through their mind. But I always love asking that question, “Right now, Mr. Customer, tell me everything you’re thinking and experiencing.” To them it’s like magic, its like they’ve taken this magic pill that’s lifted all their troubles away. Because believe it or not one of the biggest banes of most mens existence is actually finding the perfect pair of jeans. So 2011, you guys started, you tell the story.

BC: Nick Weaver and Josh West from Mississippi founded BlueDelta. Mississippi is a pretty rural state, full of good hard working people. Josh was involved in economic development here in Tupelo which is in North East Mississippi and he saw a unique thing about Tupelo, which is that its a big manufacturing garment town. One of the manufacturers that was here and had left was a contract sewing company that made 501s for Levi. So there’s this wealth of talent of folks who know how to sew blue jeans, Josh being the entrepreneur that he is decided to take advantage of that knowledge base and he got together with Nick, the kind of guy who could just sell anything to anybody, and they started putting the company together. They bought sewing machines, hired a lady named Sarah Ritchie who’s still with us - she’s been sewing jeans pretty much her whole life. 2011 the company comes into existence, 2012, starts sewing blue jeans and as with most bespoke clothing manufacturers it was a slow roll… they had to figure some things out… but then we got to that point as a company where we were confident in the product that we were making and just had to sell it. The magic of the internet: people found out about us and wanted to buy our product but we couldn’t get it to them so we started our wholesale programme with people like you. You’ve been a good one, we’re glad to have you!

RR: Thank you I’m glad to be working with you. I can’t wait for the day I can come visit you in Mississippi… So on my side what happens is, a customer comes to me with the current way they buy jeans being a problem, I tell them they’ve got to try our jeans and when they get them the first time they’ll know how great they are because they’ll be in jeans heaven. So I measure them meticulously and send this set of measures to you guys which is then translated into a paper pattern, individual for that customer…

BC: So like you mentioned we take 16 measures from each customer so you have a waist, seat, three thigh measures, a knee, a calf, co-ordinate measures for all of those so basically where you took those measures in relation to each other… we take full outset and two rise measurements which is what creates the saddle of the jean. A very important measurement because it’s what makes sure they’re not too tight or too loose in that area, they fit just right. We’ve got a guy, Johnson Benjamin, the Picasso of denim here in Mississippi! He and his patterning team draft every pant we make, so if you’re a client and get a pair of jeans from us, one of 3 or 4 people here in the shop is going to be spending about 15 minutes with your measurements drafting out that pattern, making sure that every part of the jean from the waistband all the way down to the hem is sculpted and measured just right. That jean is then cut and goes into a sewing process that takes 2 and a half hour approx, 6 or 7 sets of hands will touch your jeans along the way. We used to do it very old school where somebody would take a cut jean and it was their responsibility all the way through and we realised a couple years back, that the romance is definitely there with that idea but the practice is that some people are better at sewing waistbands, some are better at running the double needle machine and some are better at placing zippers. So we found where our talent and the folks who are working for us had specialised skills, we put them in their job and let them execute it day to day. But after the jean is sewn, it goes through a full inspection process, they look at every jean, they look at all the measurements and make sure the denim is the correct colour, its got the right colour stitching and buttons, zippers and then it ships. We ship jeans all over the world on a daily basis. I like to tell people its a very simple, complicated process. We’re making blue jeans but we do in a way that I don’t imagine there’s more than maybe a dozen companies in the world that does it the way that we do.

RR: Definitely not over here that’s for sure. Anyone listening to that would think that through all those processes you had some sort of factory the size of 12 football pitches or something, but you don’t do you, for all intents and purposes you’re still a family business.

BC: We are - we’re a little bigger now. Our company top to bottom is somewhere in the range of 35-40 people.

RR: That’s still small though, relative to output. It means that everybody knows each other! It certainly translates, we see it on our side in the customer service and so on. I mean if you want to talk in fail rate we very very rarely have a problem. The only recut we ever had was not because of sizing but because someone just went for a very heavy denim (when we first started they were much heavier) and didn’t like it so we remade it for him in something lighter. But it’s testament to my measuring and your guys’ ability to translate the information that I’m given them into this pattern that gives jeans that fit first time, it’s incredible. Why would anyone go back to buying jeans the old way ever again, why would you go through all that pain. So to talk about some of your achievements over there that we don’t see over here, you’re now the official jean of the Ryder Cup?

BC: So our product being so unique has lent us some very unique opportunities. So our storefront being in Oxford, Mississippi it’s a college town, a big college football town, and the University of Mississippi puts out professional athletes. So professional football players, professional baseball players, athletes. Guys that 6’6”, 300lbs, tiny waists, big butts and long legs, they knew about us just because we were in their town. So we were able to take those guys, put them in jeans and now we’ve got a couple hundred clients in the NFL, and then by doing it put us into the NHL and NBA a little bit. The PGA has gotten to be a good client of ours - we put jeans on the right people and we’re asked to be an official partner of the Us Ryder Cup team for the now 2021 Ryder Cup which is a Whistling Straights in Wisconsin, so we’ll have the opportunity to outfit the entire team… there’s this little known brand call Ralph Lauren that will do all their on-the-course wear and we’ll get to do all their off-the-course wear. So media events, dinners, cocktail events and so on, so we’ll have their entire team outfitted. Also in about a month I’ll be going for the PGA Championship at Kiowa Island in South Carolina and we’ll get to fit all of those guys and watch some good competitive golf in September.

RR: so I always that that American Footballers had better of the pitch dress sense than English footballers. Because footballers just seem to want to wear jeans that make them look like clowns. You know that high end designer stuff that costs £2k-£4k from Balenciaga etc… so that’s a work in progress over here but I’m greatly inspired and I will redouble my efforts to try and tidy up those that play sports by kicking a ball as opposed to handling it. Although our rugby players aren’t too bad.

BC: Well big butts, big thighs and long legs are kind of a speciality of ours so if you can put some on some soccer players we would love that because that’s one market we haven’t gotten into over here.

RR: So something else over here that is on trend is the environment. Traditionally any form of mass-produced clothing is known for being bad for the environment, not just in the way it’s produced but throwaway fashion is no good because it ends up in landfill and so on. We know that the jeans that we’re making are produced from a form of raw denim so that’s great - you’re very selective over the types of fabrics you work with?

BC: Unfortunately denim and sustainability just don’t go hand in hand. Denim is an incredibility - I don’t want to say wasteful but maybe that’s the right word - material to make. I read somewhere that every pair of jeans you buy takes about 2000 gallons of water to make. I’ve seen that stat a couple times so I believe it but I’m not a scientist so don’t know if you can trust me on it. The way we look at it is we can’t do anything about the way denim is made. So our view is that the average person owns 7 pairs of jeans. Our goal is for it to be that you make it to 3 or 4 pairs of jeans that you love and that will last a long time as opposed to you going out and replenishing that 7 all the time. One of my big qualms with denim as it is and American culture is that its very throwaway. You spend $20-$30 on cheap jeans, you were them hard for 6 months and then get rid of them. That’s not something I like whether in denim or anything I buy. |If I’m going to spend money on something I want it to last. We as a company, our goal is that if someone is going to spend the money on our product we want it to last for them a long time and we want to get them to where they don’t have to buy a pair of jeans every 6 months. Maybe you get a couple at the beginning but after that it’s once a year - get yourself another pair to expand the variety not to replace what you already have.

RR: I frequently have that conversation where they say, “I’m buying £60-£100 jeans why would I spend 4-5 times as much on bespoke?” and my answer is, how many jeans do you have and the answer is anywhere between 12-15 even. Out of those how many do they love wearing? I very rarely get someone tell me it’s more than two, often it’s just one or even none. OK fine, if you’re spending £100 on jeans and you have 12 of them, wouldn’t you have rather spent £1000 on two pairs that you love so much that you have to fight every day to decide which pair you’re going to put on. And also any problems you just give them back to us and we’ll fix them up for you. That then begins to make more sense to them. So it’s about shifting people’s attitudes and perceptions, how they think about and value these things as well.

There’s also the story that denim tells as it ages - and with throwaway jeans you lose that if you chuck them in the bin every six months.

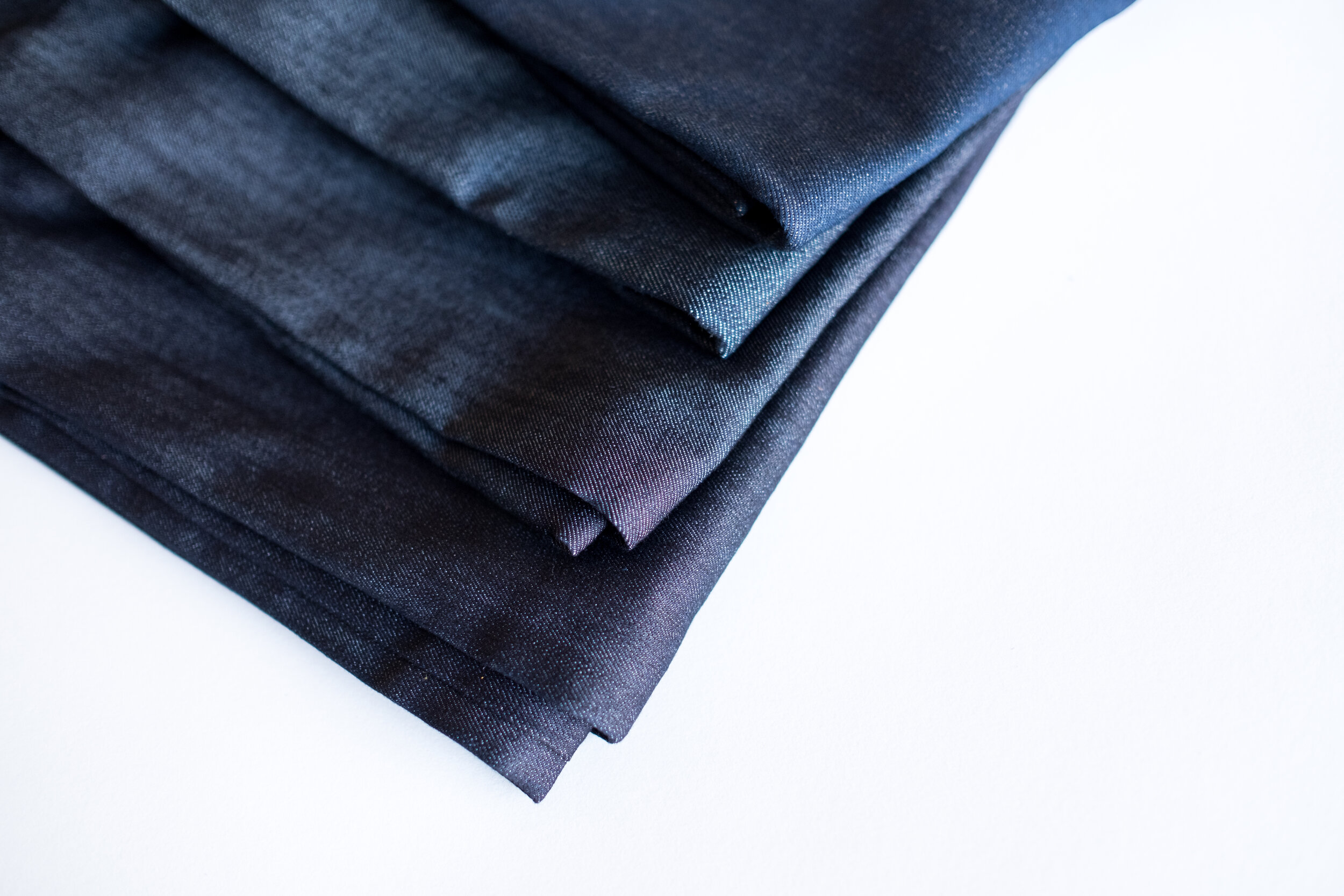

BC: There’s a certain romance to a good pair of jeans. Our raw denim starts out as a dark, more of dress denim, it’s not going to have some of that pre-distressing or acid wash that is sometimes popular. It’s going to start as a blank canvass and you get to put life into that garment. So one thing we always tell our clients - our jeans are like a baseball glove, or a leather binder, or a pair of shoes where you get it where it’s brand new. Its a product that'‘s got some… it’s not soft… you get to break it in and give it that feel that it develops. You don’t want to buy a pair of used shoes, you want to get them brand new and let your foot make the imprint in them. So I was looking at your jeans that you’ve got on there, we completed them August 2015 so coming up to 6 years. So you’ve got what a 7th or 8th of your life with those jeans. That’s one of the beautiful things, a great thing about our jeans. You get this brand new item and then it’s all you from there.

RR: When we say break in we are talking about people putting their own imprint on these things - these garments are comfortable from the word go. I have a quote from one of our youngest customers who just had his first pair: “My waist and legs are slightly disproportionate. If something fitted my waist it was too tight on my legs. Also the materials were very restrictive, denim looked nice but wasn’t comfortable or functional. When I first put them on I squatted down and was surprised at the amount of stretch in them. I was wearing jogging bottoms when I got the jeans and I can’t feel much difference, they are that comfortable. I’ll never buy off the rack jeans again. I can’t go back after trying these. They are versatile, durable, and comfortable. The perfect item of clothing. If you’re thinking about bespoke take the plunge. The right pair of jeans can last years, why not spend those years in comfort?” That just says it all… and every single time the feedback we get when people have tried custom jeans.

RR: Just looking ahead to the future now, because we have this amazing stat that at any time half the world’s population are wearing jeans (and probably 80% of those are wearing jeans that don’t fit!), where have you guys seen the future for the denim industry and your place within it?

BC: Pre-Covid the full suit was starting to see an exit. People were looking to buy our jeans to pair with a sports jacket as part of a smart casual look. Now during the pandemic people have resorted to sweat pants or jogging bottoms or shorts while sitting in their home offices. But we’re all getting our vaccines and hopefully in the next however many months, the world will find itself back in our offices and we will need something to wear. I don’t think companies will require a full suit or a tie every day… if you come in and you look nice and professional wearing a sharply fitted pair of jeans and a nice shirt or sports jacket, then you’ll fit the bill. So there is a unique opportunity to see some growth in that category, not that denim needs help to be more popular because of the stat we quoted, but we’ll continue selling jeans and hopefully that’ll become a part of the Monday to Friday work uniform. But we’ll see if that really happens though!

RR: Over here in the UK it’s really funny because again at the start of Covid people’s dress sense just went out the window and into the gutter. Then as times progressed people saying they won’t wear a suit but they’ll still need some form of the shirt, jacket and trouser combination. Whether that’s jeans and a sport coat or whatever, but those three basic components will remain the same. Or they might go back to wearing a suit but may never wear a tie again. Where jeans will come into play, I think - I wear jeans on certain days. My favourite wash is always very dark, like the black on blue that we do and often people can’t tell that I’m wearing jeans, or it’s not obvious/ They’re still smart enough and tailored enough, I always wear them with a shirt and I always wear a waistcoat, tie and smart casual jacket. They don’t scream jean when people look at them. I think there is a home in the office space for a much smarter type of jean and all these darker washes that have become more popular recently will become the mainstay. Obviously the alternative to that is the classic chino. The difficulty for guys, and girls, though I think girls are better at selecting their clothing when going shopping, whereas guys are more like a military strike - not much thought, just grab stuff and get out, if it fits it fits and if it doesn’t well… the question I get asked is “you know that jeans with jacket look, where it all looks like it fits how do I achieve that?” And I just say to them you get jeans that fit you properly.

BC: So we have a saying that we like to use in BlueDelta because as you mentioned most people don’t have a well-fitted pair of jeans. A friend of the company came in one time and on his first pair of jeans he said, “I wear jeans and a jacket most days but I have very poorly fitted jeans. It’s like I have a business mullet. I’m well put together in the front but terribly in the back.” We joke that we like to solve the business mullet. You’re put together up top, you’ve got a nice shirt and a nice sports jacket, but the jeans need some work. Let’s get the clippers out and take care of the jeans part.

RR: That’s brilliant - over here to tell someone they have a mullet is an insult so I’m going to start telling people I need to de-mullet your outfit. Brilliant. Thank you so much for your time today, I’m sure there’s things we haven’t spoken about that people will want answers to then please send your questions to me or put them in the comments below.